PRODUCTS

PRODUCTS

Feedback

If you have any questions, please leave your contact information, or contact us, thank you for your support and trust, we will wholeheartedly provide you with high quality products and services!

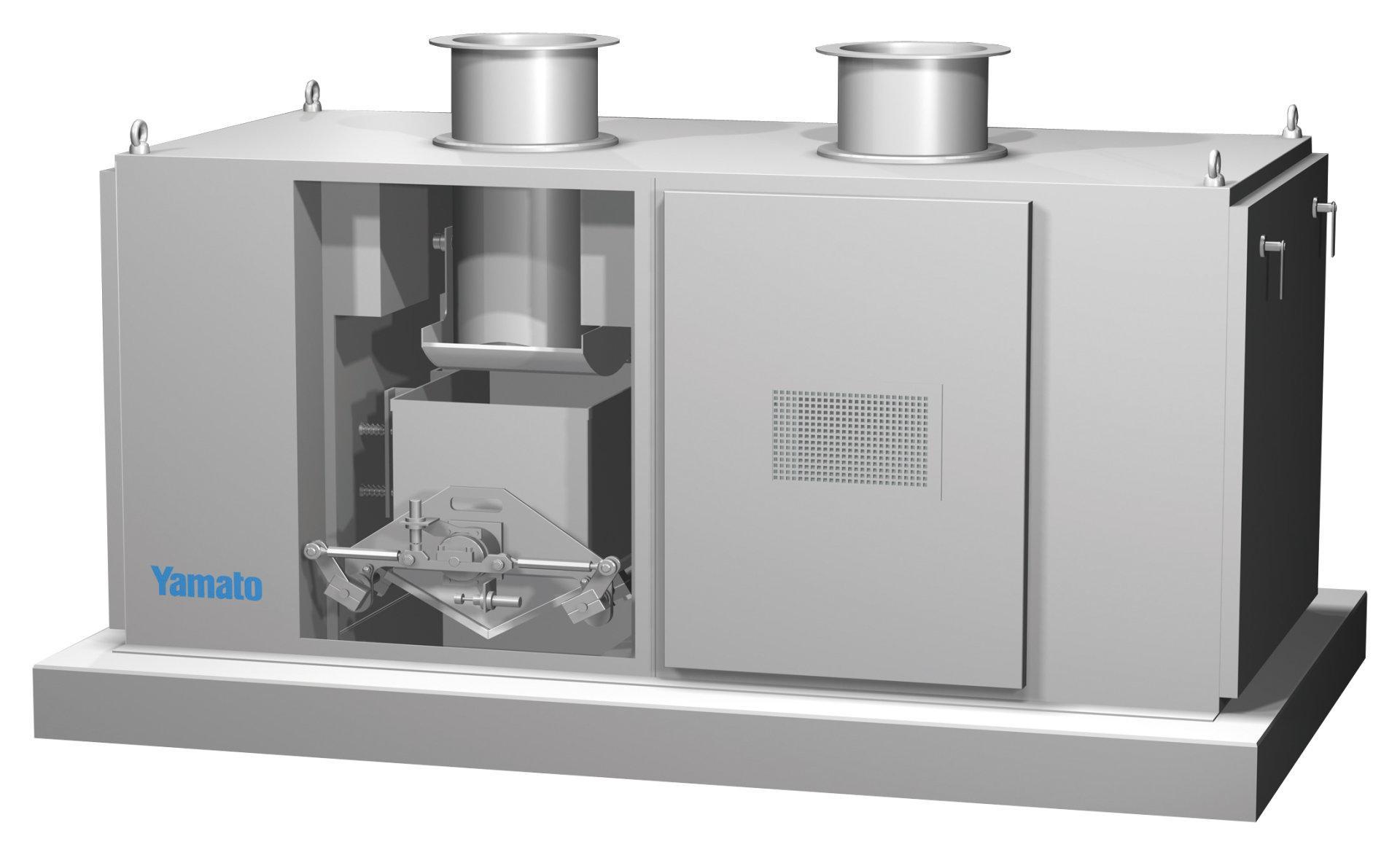

Packing scale-FNL-308CC packing scale

Category:

Packing scale series

Product Accessories:

Description

F NL-308CC quantitative packaging scale

High precision and high speed bring high profits, safety and reliability, and reduce foreign matter mixing.

Improved profits through high accuracy and high speeds, as it provides safety and security through reduced contamination from foreign objects.

Optimized feeding device to achieve high

-speed weighing High-speed weighing by optimal Loading gates

Foreign matter mixing prevention machinery (patent pending) makes weighing clean

Clean weighing by machinery that reduces foreign objects(patent pending)

Touch screen controllers make adjustment operations simple

Adjustment operations are made easy by touch-panel controllers(Option)

The 308 series packaging scale is a novel high-speed, high-precision packaging scale newly developed by Japan Yamato following the 306CC.

It is suitable for the packaging of high-priced materials such as MSG, PE/PVC powder and granules, which can save a lot of high-priced materials for users and create huge economic benefits.

Features

● High precision to increase productivity

High accuracy leads to improved yields

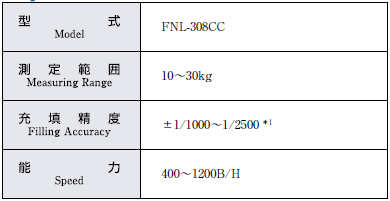

-Increased accuracy from 1/1000 to 1/2500-

- Accuracy raised from 1/1000 to 1/2500 –

For example, packaging 25kg bags of raw materials at a price of 12 yuan/Kg, when the accuracy is increased from ±25g to ±15g...600 bags per hour, 4800 bags per day (8 hours), 140,000 bags per month, 1 year About 1.7 million bags, about 17 tons by weight. From the perspective of economic benefits, it means that income will increase by 200,000 yuan.

For instance, when you pack 25 kilograms of raw material with each kilogram priced at 12 Yuan, and when accuracy is raised from ±25 grams to ±15 grams…Then when 600 bags are replenished an hour, that would make 4800 bags per day (based on eight-hour days), approximately 140000 bags per month, or 1.7 million bags a year, which calculates to about 17 tons. In monetary terms, that would mean a yield effect gain of 210 thousands Yuan.

● High speed reduces initial investment

Cutting initial costs through high speeds

- From 1 to 2 linked together, reducing the initial investment -

- Reducing initial investments by going from two lines to one. -

For example, when 2 units are changed to 1 unit , and 3 units are changed to 2 units, it becomes possible to save equipment installation space, high-speed operation shortens the running time of single unit, saves electricity and reduces maintenance time by half, reducing operating costs.

For example, when it becomes possible to go from two to one lines or from three to two lines…then installation space is conserved, line operation times are shortened through high speeds, power usage is cut, and even maintenance times are halved, reducing your running costs.

● No foreign matter mixed in

No contamination from foreign objects

-Safety ● peace of mind-

- Safe and secure -

Since all sliding parts are separated from the metering chamber in design, there will be no foreign matter and wear particles mixed in.

There is never any contamination from foreign objects from wear debris, because the design separates all sliding parts from the weighing chamber.

Specifications

Applications

Resin particles, beans, polished rice, fertilizer, feed and other materials with good fluidity below 150μm.

Rasin pellets, beans, rice, fertilizers, feeds those less than 150μm with good flowing characteristics.

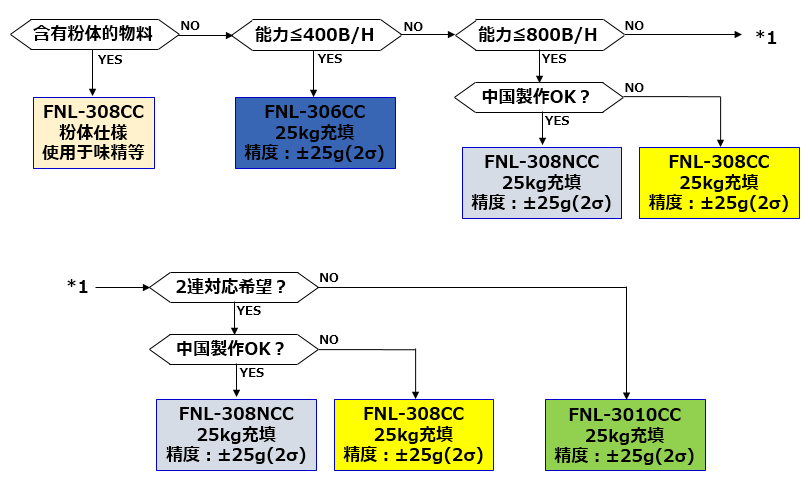

Comparison of various packaging scales

How To Choose Packaging Scale

A MSG company has used more than 10 25kg 308CC packaging scales in the 80~95# MSG packaging. On average, each bag saves 50~80 grams of MSG, which is equivalent to RMB 0.4~0.64 . The investment can be recovered within three months. User praise.

The packaging scale of a PCV particle manufacturer has a speed of 800 bags/h and a precision pre-addition of 100g/time. The speed of Yamato Packing Scale is 1000 bags/h, and the precision pre-addition is 25g/time. According to this calculation, 800 bags/h*24h*30 days* (100-25) = 43.2 tons, that is to say: 1 scale can save 43.2 tons of raw materials in one month, worth 280,000. One scale can be saved in one month. As far as the packaging line is concerned: Compared with the packaging machine, the scale is the chef and directly produces economic benefits.

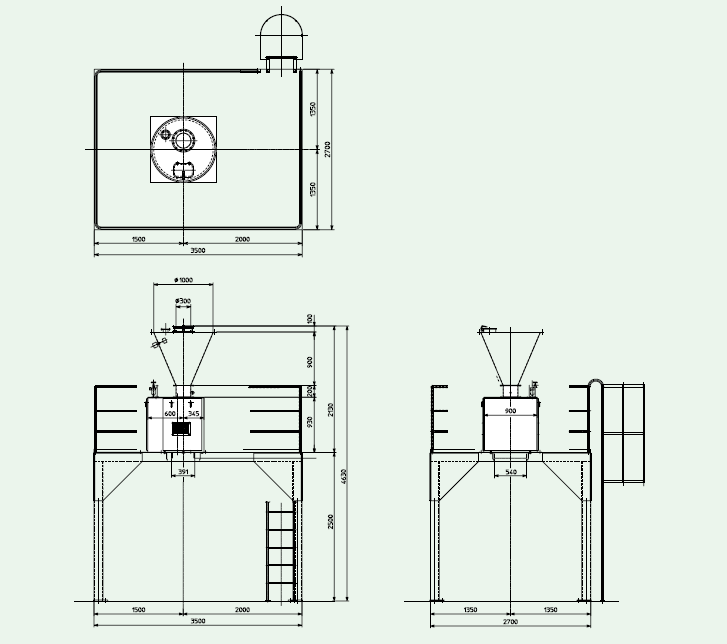

Dimensions (mm)

Keyword:

ONLINE MESSAGE

Related products